Why Winter is the Perfect Time to Uncover Your Building's Hidden Heat Loss

The developer promised cutting-edge insulation and minimal energy bills.

The Johnsons moved into their dream eco-home in Bridlington just before Christmas. The developer promised cutting-edge insulation and minimal energy bills. Yet by February, they were spending £340 monthly on heating, double the projected costs, whilst the master bedroom remained stubbornly cold despite the radiator running constantly.

The site manager dismissed their concerns during the snagging process. "New builds always take time to settle," he insisted. "The heating system needs balancing." But thermal imaging told a different story entirely.

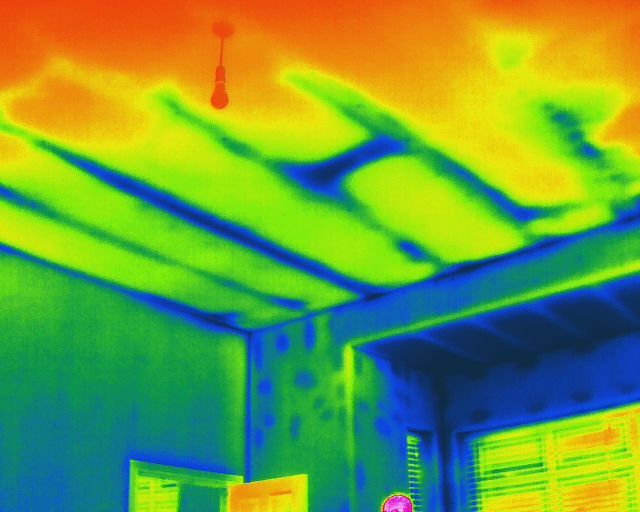

When a qualified thermographer surveyed the property in March, the internal thermal images revealed the truth: missing insulation behind the bedroom's external wall, thermal bridging through poorly installed cavity closers, and significant air infiltration around the new window frames. Visual evidence the site manager couldn't dispute.

The Science Behind Winter's Thermal Window

Internal thermography works on a simple principle: heat always moves from warm areas to cold ones, and infrared cameras can detect these temperature differences with remarkable precision. But here's what makes winter months particularly valuable the cold, dry conditions provide the sharp temperature contrast needed for accurate thermal imaging, with inspections typically conducted between September and May in the UK.

When outdoor temperatures drop below 5°C and indoor heating maintains 18-21°C, you create a temperature differential of at least 15°C. This stark contrast reveals thermal anomalies that remain hidden during milder weather. Think of it as nature providing the perfect laboratory conditions for thermal investigation.

Professional thermographers use calibrated thermal imaging cameras capable of detecting temperature variations as small as 0.01°C. The UK Thermography Association recommends cameras with a minimum 320 × 240 pixel detector for building surveys, with higher specifications required for commercial buildings.

What Internal Thermography Reveals That External Surveys Miss

Most building owners assume an external thermal scan tells the whole story. They're wrong. External 'hot spots' may not necessarily identify the corresponding internal 'cold spot', and only a basic impression of thermal performance can be determined from external surveys alone.

Internal thermography provides the complete picture:

Thermal Bridging Detection Cold spots appearing on internal walls often indicate structural thermal bridges – areas where conductive materials create pathways for heat transfer. A Category 1 Thermographer can identify these bridges precisely, showing exactly where insulation has failed or where structural elements conduct heat directly through the building envelope.

Air Infiltration Mapping Draughts aren't always obvious to occupants, but thermal imaging reveals air movement patterns with startling clarity. When combined with blower door testing, internal thermography locates the exact sources of air infiltration from poorly sealed windows to gaps around service penetrations.

Insulation Performance Assessment Missing, displaced, or poorly installed insulation creates distinct thermal signatures visible only from inside the building. These patterns show not just where insulation is absent, but where it's compressed, wet, or performing below specification.

Hidden Moisture Detection Damp insulation loses up to 50% of its thermal performance. Internal thermal imaging identifies moisture-compromised areas before visible signs appear, preventing both energy loss and potential structural damage.

The New Build Challenge: When Eco-Promises Fall Short

Modern eco-homes promise exceptional thermal performance, but construction reality often differs from architectural drawings. The Johnsons' experience illustrates a common problem: developers focussing on compliance rather than performance.

Common New Build Thermal Issues:

- Insulation gaps around service penetrations

- Thermal bridging through structural connections

- Poor cavity wall insulation installation

- Window and door sealing failures

- Ventilation system imbalances affecting heat distribution

The Snagging Process Problem: Site managers often dismiss thermal comfort complaints as "teething problems" or user error. Without visual evidence, homeowners struggle to prove construction defects. Internal thermal imaging transforms subjective comfort complaints into objective technical evidence.

The Professional Advantage: Why Experience and Qualification Matter

Not all thermal surveys deliver actionable results. Thermographers must be fully trained to a minimum of PCN/ITC Level 1 (ISO 18436) and use calibrated thermal imaging equipment to ensure accuracy and reliability.

At Dee4Drones, our Category 1 Thermographer brings over 10 years of professional drone and thermal imaging experience since 2013.

This expertise combines:

- Understanding of building physics and heat transfer principles

- Knowledge of construction methods and material properties

- Expertise in environmental conditions required for accurate readings

- Professional-grade equipment calibrated to traceable standards

- Ability to distinguish between thermal anomalies and normal building behaviour

This depth of experience proves crucial when interpreting thermal images. What appears as a simple cold spot might indicate multiple issues – from structural thermal bridging to ventilation system problems – each requiring different solutions.

The Dee4Drones Difference: With over a decade of experience operating throughout Yorkshire, we understand the specific challenges facing property owners in our region. From coastal properties in Bridlington dealing with salt-laden air affecting building fabric, to inland developments facing harsh winter conditions, our local knowledge ensures surveys are planned and executed with regional factors in mind.

Optimal Winter Survey Timing

Winter provides excellent conditions from November through March, but specific timing within this period matters:

Best Survey Conditions:

- Early morning (6:00-9:00 AM) before solar heating affects results

- Minimum 15°C temperature difference between inside and outside

- Dry conditions (moisture on surfaces interferes with readings)

- Building heated to normal operating temperature for 12+ hours

Peak Performance Months:

- December-February: Maximum temperature differentials

- November & March: Good conditions with longer daylight hours

- Late autumn/early spring: Ideal for follow-up surveys after remedial work

Weather to Avoid:

- Direct sunlight on building surfaces

- Recent precipitation on external walls

- Windy conditions that affect surface temperatures

- Foggy conditions that reduce thermal contrast

Translating Thermal Data Into Maintenance Action

Internal thermography doesn't just identify problems – it provides tradespeople with precise locations and evidence-based priorities for remedial work.

For Homeowners in Snagging: Thermal images serve as irrefutable evidence when challenging developers. Instead of subjective complaints about "cold rooms," you present objective thermal data showing temperature differentials and construction defects.

For Building Managers: Thermal evidence helps prioritise remedial work based on heat loss severity rather than guesswork. A thermal image showing a 5°C temperature differential indicates more urgent attention than a 1°C variation.

For Contractors: Having thermal maps before starting work eliminates diagnostic time and reduces the risk of missing related issues. When repairing insulation, thermal images show whether adjacent areas also require attention.

Our Professional Reporting: Dee4Drones provides comprehensive thermal survey reports with clear analysis and specific recommendations. Each report includes thermal images with temperature data, problem identification, and practical solutions that contractors can implement immediately. We explain technical findings in straightforward language, ensuring property owners understand both the issues and the remedial options.

The Commercial Case for Winter Surveys

UK homes account for 26% of all the country's energy use, with space and water heating making up around 80% of total domestic energy consumption. For new builds promising high efficiency, thermal performance failures represent significant financial and environmental costs.

A comprehensive internal thermal survey typically costs £250-£399 depending on building size, but can identify energy losses costing thousands annually. More importantly, early detection during snagging periods ensures developers rectify issues under warranty.

Regulatory Compliance: BREEAM assessments award credits for thermal imaging surveys conducted by Level 2 certified thermographers in accordance with ISO 18436-7, making winter surveys valuable for sustainability certifications.

Warranty Protection: For new builds, winter thermal surveys during the first year identify construction defects whilst they remain the developer's responsibility to rectify.

Beyond Heat Loss: What Else Winter Reveals

Internal thermography in winter conditions exposes more than thermal performance:

- Construction quality verification in new builds

- Underfloor heating system performance and leak detection

- Ventilation system efficiency and ductwork integrity

- Service penetration sealing effectiveness

- Window and door installation quality

Each discovery provides opportunities for warranty claims or proactive maintenance rather than reactive emergency repairs.

The Resolution: Evidence-Based Results

The Johnsons' thermal survey revealed three critical construction defects in their eco-home. Armed with thermal images clearly showing missing insulation and air infiltration patterns, they approached their developer with undeniable evidence.

The remedial work included:

- Retrospective insulation installation behind the bedroom wall

- Cavity closer replacement to eliminate thermal bridging

- Professional window resealing to prevent air infiltration

The developer completed all works under warranty. The Johnsons' February heating bill dropped from £340 to £145, and the master bedroom now maintains comfortable temperatures consistently.

More importantly, the thermal evidence prevented years of excessive energy costs and potential moisture problems from uncontrolled air infiltration.

Yorkshire's Trusted Thermal Imaging Specialists

Since 2013, Dee4Drones has helped Yorkshire property owners solve thermal performance challenges through professional thermal imaging services. Our CAA-licensed operations and TQUK Level 5 Commercial Drone Chief Pilot qualification ensure every survey meets professional standards whilst delivering practical, actionable results.

What sets us apart:

- Over 10 years of professional thermal imaging experience

- Local Yorkshire knowledge and expertise

- Comprehensive, clear reporting that contractors understand

- Professional service from initial consultation through to final recommendations

- Competitive pricing with transparent, fixed-cost surveys

We understand that thermal surveys can seem technical and complex. Our approach focuses on making the findings clear and the solutions practical. You receive thermal evidence you can use confidently when dealing with developers, contractors, or insurance companies.

Making Winter's Cold Work for You

Winter's harsh conditions aren't just something to endure they're the perfect tool for revealing exactly where your building's warmth disappears. Whether you're challenging a developer during snagging or investigating energy performance in an existing property, internal thermal imaging provides the visual evidence needed to demand action.

Our experienced Category 1 Thermographer uses professional-grade equipment to document thermal defects that site managers and contractors cannot dismiss. The thermal images become your proof, your justification for remedial work, and your pathway to achieving the thermal performance you were promised.

Don't spend another winter wondering why your energy bills are sky-high whilst rooms remain cold. Get the thermal evidence you need to fix the real problems, not just treat the symptoms.